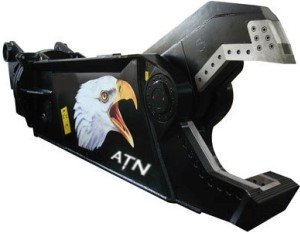

» New Machines » ATN » Scrap Shear

Scrap shears RHS by ATN

High performance in the industrial demolition sector

ATH's RHS scrap shears are universally applicable in the field of industrial demolition and have been specifically designed for cutting as well as for preparing the subsequent recycling of ferrous material (steel beams, pipes, tanks, rail cars, etc.).

Based on the knowledge acquired over decades, ATN has developed a completely novel design and concept for this high-performance shears. Only modern types of steel, which are characterized by low weight, resistance, and high wear resistance, are used in production.

Rapid flow valve for faster jaw opening and closing

All models of the RHS production series are equipped with a rapid flow valve to ensure extra short periods of time regarding the opening and closing of the movable jaw. In addition, the RHS series has a high-performance cylinder for exceptional demolitional power under all kinds of working conditions.

The hydraulic 360° rotational drive is a standard feature available on all models and enables a precise and fast positioning of the tool. Further, all models of the RHS series have a stabilizing guide for the movable jaw to ensure precise cutting.

All rebar cutting blades can be exchanged quickly and easily, which means that there is no need for time-consuming welding which would have to be carried out by specially trained personnel. This way, both maintenance costs and machine downtimes can be significantly reduced.

| Tool Data | RHS – 400 | RHS – 650 | RHS – 1100 | RHS – 2100 | RHS – 3300 |

|---|---|---|---|---|---|

| Excavator (Bucket) t | 4-5 | 5,5-6,5 | 9-17 | 18-27 | 28-37 |

| Excavator (Stick) t | 2-3 | 3,5-4,5 | 7-10 | 13-20 | 20-28 |

| Operating weight kg | 380 | 650 | 1100 | 2100 | 3300 |

| Jaw opening mm | 195 | 240 | 350 | 445 | 565 |

| Tool Data | RHS – 4700 | RHS – 5700 | RHS – 7700 | RHS – 10000 |

|---|---|---|---|---|

| Excavator (Bucket) t | 38-50 | 50-65 | 65-90 | 90-110 |

| Excavator (Stick) t | 26-38 | 38-45 | 40-60 | 60-80 |

| Operating weight kg | 4700 | 5750 | 7700 | 10100 |

| Jaw opening, mm | 670 | 760 | 830 | 965 |

Subject to errors and technical changes. Illustration similar.